So you reduced the deadband a bit is that correct?

Hey you said you wanted it without commentary, now you want explanations.

You should find plenty of that in the flow meter thread. You could save some time by reading just the last page where I'd got most of my information and the methods sorted out. I'm more than willing to help but asking me start rewriting stuff because you don't want to read is going a bit far.

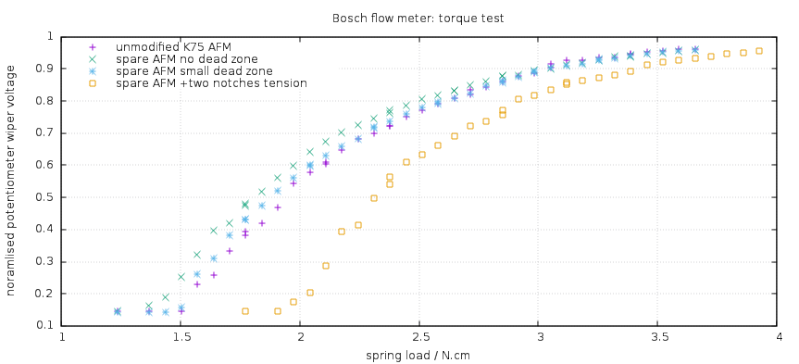

The last graph on that page shows the effect of different 'dead zones' compared to a non modified unit and stepping the preset on the spring tensioner. I think that is what you want to look at.

You could try measuring at the barn door as Charlie did ( post and his graph disappeared ). This will cover some questions if done carefully I went for measuring torque because it's a torque driven device, not displacement driven, and to start with I wanted to see how linear the output voltage was, or rather how close to logarithmic it was, just to gain understanding.

There would be some advantage to deciding from barn door testing whether it needed opening up. But only saving the question of resealing it afterwards.

If you are just pushing on the end of the vane and measuring output voltage as a function of distance and not force then you are not testing possible mechanical problems. If there are tight spots in the mechanism you will miss them. Also I don't know whether this would be accurate enough to determine whether output was stable or not.

Charlie's graph had a flier. One that was plenty bad enough to cause noteworthy running problems if it was indeed due to bad contacts. It could just have been experimental error. That would need a few runs on a good unit to see how repeatable the results were. You need to ensure that you can get repeatable results first.

I'll give you some practical tips if you get that far.

Even if you do my buckets and syringes method you will need to exercise lots of care to get stable graphs like I did. There is some experimental jitter in the graphs but not so much as to mask the results. Even quite small differences in dead zone produced clearly different curves.

I could improve the method accuracy but I think it worked well enough to achieve the required result.

Re: Throttle response Tue Apr 12, 2016 11:08 am

Re: Throttle response Tue Apr 12, 2016 11:08 am