1

I really need you guys Fri May 03, 2013 3:25 pm

I really need you guys Fri May 03, 2013 3:25 pm

ibjman

Life time member

I know this is slightly "off Topic" as it relates to automotive gears, not motorcycle. Still, I hope it has relevance because out bikes have similar final drive gears. I have a Used Chevrolet Differential on the bench & I'm attempting to prepare it (CHEAPLY) to replace the one on my vehicle. Following is the narrative of what I have and the help I'm asking for.

The object is dependable not necessarily "whine free"......so I'm replacing few if any parts.

Hypoid Gear set adjusting

This differenial gear set has NO backlash.

There is no history known on who may have installed the gears/bearings (if at all)

No road test was available before inspection.

It seems obvious that because there is NO backlash, that something has been replaced and

is not factory original.

The object of this repair is to adjust the gear(s) positions to create suitable backlash while

achiving the best comprimise of mesh pattern.

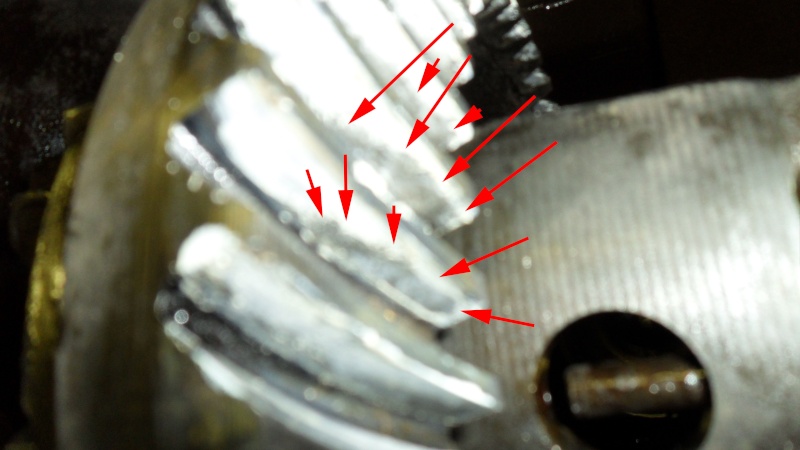

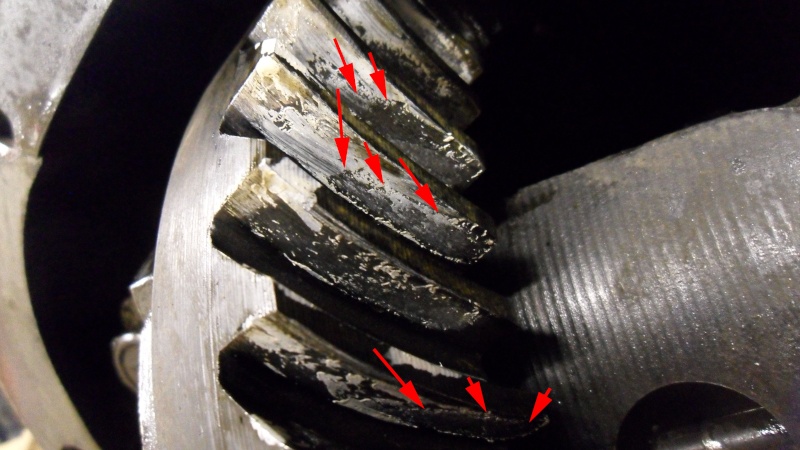

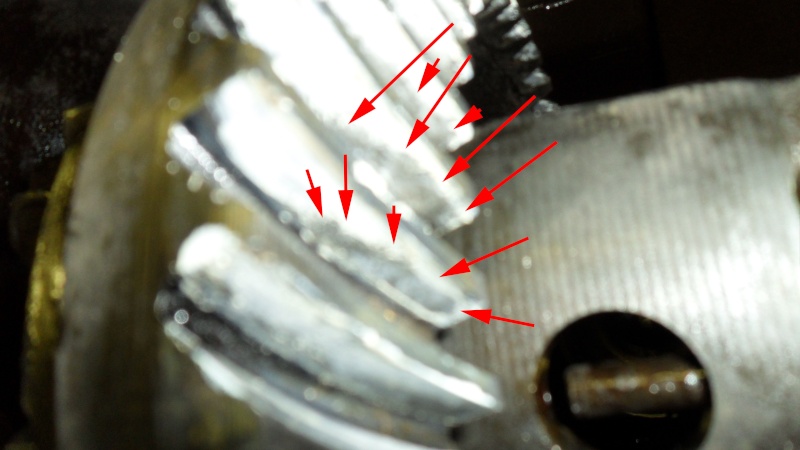

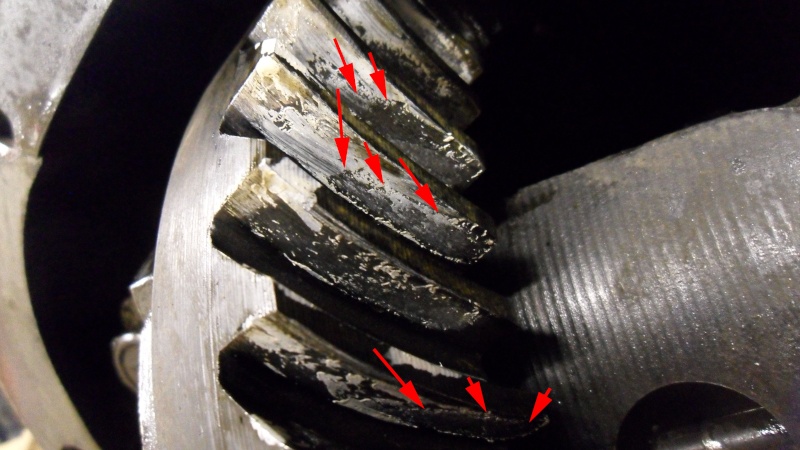

There are 6 Gear pattern Photos below.

Photos 1-4 are of the drive side of the Ring Gear.

Photos 5 & 6 are on the coast side of the ring gear.

To me it appears that on the drive side, the pattern is running very low on the gear tooth,

almost off the bottom and slightly deeper in the gear than optimal.

Conversly, the pattern on the coast side of the same teeth is running High up towards the

outer circumferance of the ring and about proberly centered in the depth of the gear tooth.

I have to move either the ring gear out (left) away from the pinion or I need to move the pinion

gear forward away from the ring to create backlash. I do not have the exact spec yet, but I will

look it up in the book. I'm guessing (with no professional knowledge of gearing) that I'm

shooting for about 3 to 6 one thousanths of an inch backlash, measured at the ring gear outer

edge.

Now, I really need some help on this from some of you down under engineer types that

understand the exact relationship between hypoid gears and how movement of either effects

the other.

.

Obviously, If it works out the right way, the ring is easier to shim left away from the ring than

the pinion is to remove the inner bearing & crush sleeve to change the pinion depth.

Please help me decide which way to move what.

Thanks ahead of time.......ibj...

[img]http://i79.ser[url=https://servimg.com/view/17895439/229] vimg.com/u/f79/17/89/54/39/pull-410.jpg[/img][/url]

vimg.com/u/f79/17/89/54/39/pull-410.jpg[/img][/url]

The object is dependable not necessarily "whine free"......so I'm replacing few if any parts.

Hypoid Gear set adjusting

This differenial gear set has NO backlash.

There is no history known on who may have installed the gears/bearings (if at all)

No road test was available before inspection.

It seems obvious that because there is NO backlash, that something has been replaced and

is not factory original.

The object of this repair is to adjust the gear(s) positions to create suitable backlash while

achiving the best comprimise of mesh pattern.

There are 6 Gear pattern Photos below.

Photos 1-4 are of the drive side of the Ring Gear.

Photos 5 & 6 are on the coast side of the ring gear.

To me it appears that on the drive side, the pattern is running very low on the gear tooth,

almost off the bottom and slightly deeper in the gear than optimal.

Conversly, the pattern on the coast side of the same teeth is running High up towards the

outer circumferance of the ring and about proberly centered in the depth of the gear tooth.

I have to move either the ring gear out (left) away from the pinion or I need to move the pinion

gear forward away from the ring to create backlash. I do not have the exact spec yet, but I will

look it up in the book. I'm guessing (with no professional knowledge of gearing) that I'm

shooting for about 3 to 6 one thousanths of an inch backlash, measured at the ring gear outer

edge.

Now, I really need some help on this from some of you down under engineer types that

understand the exact relationship between hypoid gears and how movement of either effects

the other.

.

Obviously, If it works out the right way, the ring is easier to shim left away from the ring than

the pinion is to remove the inner bearing & crush sleeve to change the pinion depth.

Please help me decide which way to move what.

Thanks ahead of time.......ibj...

[img]http://i79.ser[url=https://servimg.com/view/17895439/229]

vimg.com/u/f79/17/89/54/39/pull-410.jpg[/img][/url]

vimg.com/u/f79/17/89/54/39/pull-410.jpg[/img][/url]