1

High Ratio gears and final drive. Changing gears and bevel box pinion removal. Sun Jun 19, 2016 9:52 am

High Ratio gears and final drive. Changing gears and bevel box pinion removal. Sun Jun 19, 2016 9:52 am

touchwoodsden

Silver member

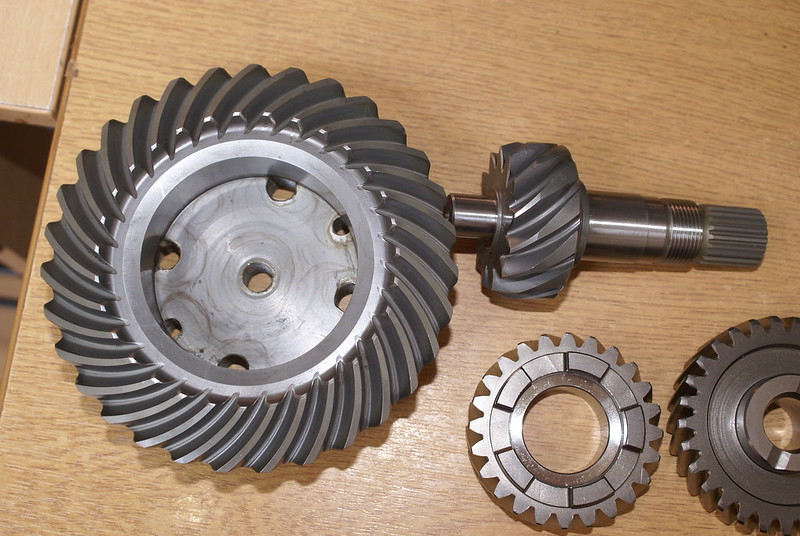

I am changing some of the gears in my gearbox because I need higher ratios for my Mercedes Smart Diesel engined K 100. I’m also changing the final drive ratios and one of the guys in Germany as had a whole gear set cut. It basically doubles the overall ratio.

The gearbox is done. Removing the large gear of the intermediate shaft (the centre top one in the gears shown on the photograph below) needs a lot of pressure. 10 tonnes wouldn’t. 20 tonnes wouldn’t touch it. It needs 40 tonnes. The centre shaft is non-serviceable-allegedly

Here is the cluster before changing the gears. You can see the new shiny years adjacent to what they are going to replace.

DSC04621

DSC04621

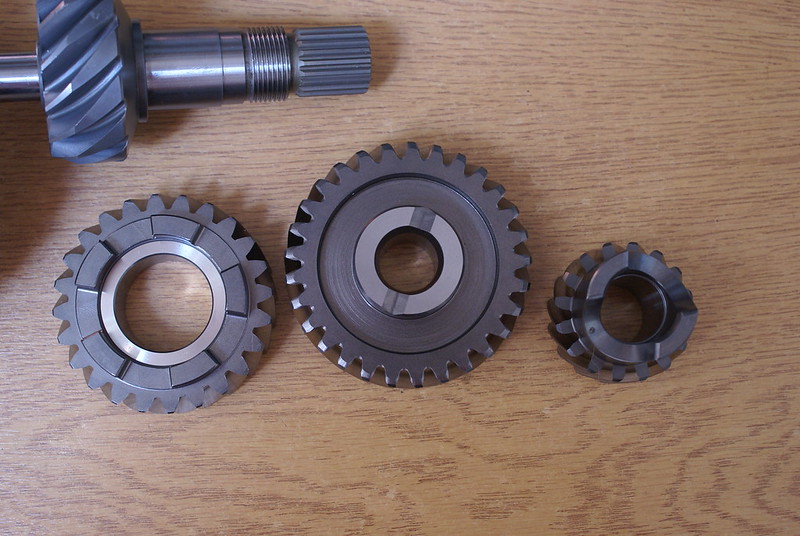

Taking the final drive apart is not for the fainthearted. I’m sure that shimming it up, on rebuild, is going to be “interesting”. Mine is now in a zillion pieces and ready for reassembly.

Don’t even attempt to strip the K 100 final drive unless you have a 36 mm impact socket, a long bar, and a tool to remove the 4 slotted ring nut which holds in the final drive pinion. I made the tool by welding 4 wings onto an old socket. They are both v tight. The manual says use heat.

DSC04816

DSC04816

DSC04819

DSC04819

Because I’m replacing both the crown wheel and the pinion, all the parts which fit on the crown wheel and pinion have to be removed. The one job that took longer than anything else was removing the inner race of the nose of the pinion which fits into the needle roller bearing in the aluminium housing. There is nothing to get the bearing puller on.

The large bearing came off with the help of a 10 ton press and the centre part of the crown wheel (the aluminium bit) succumbed to a few tonnes less.

I’ve now got to think about putting it back together and doing all the correct shimming. Deep joy.

I do have one problem and that is that the input splines on the pinion of the final drive has 20 splines and my shaft is 16 splines. I may need to find another shaft. I’m assuming that all the front of the driveshafts are 16 otherwise I might have to change gearboxes or make hybrid shaft.

I just thought I’d share this little gem with you.

The gearbox is done. Removing the large gear of the intermediate shaft (the centre top one in the gears shown on the photograph below) needs a lot of pressure. 10 tonnes wouldn’t. 20 tonnes wouldn’t touch it. It needs 40 tonnes. The centre shaft is non-serviceable-allegedly

Here is the cluster before changing the gears. You can see the new shiny years adjacent to what they are going to replace.

DSC04621

DSC04621 Taking the final drive apart is not for the fainthearted. I’m sure that shimming it up, on rebuild, is going to be “interesting”. Mine is now in a zillion pieces and ready for reassembly.

Don’t even attempt to strip the K 100 final drive unless you have a 36 mm impact socket, a long bar, and a tool to remove the 4 slotted ring nut which holds in the final drive pinion. I made the tool by welding 4 wings onto an old socket. They are both v tight. The manual says use heat.

DSC04816

DSC04816 DSC04819

DSC04819 Because I’m replacing both the crown wheel and the pinion, all the parts which fit on the crown wheel and pinion have to be removed. The one job that took longer than anything else was removing the inner race of the nose of the pinion which fits into the needle roller bearing in the aluminium housing. There is nothing to get the bearing puller on.

The large bearing came off with the help of a 10 ton press and the centre part of the crown wheel (the aluminium bit) succumbed to a few tonnes less.

I’ve now got to think about putting it back together and doing all the correct shimming. Deep joy.

I do have one problem and that is that the input splines on the pinion of the final drive has 20 splines and my shaft is 16 splines. I may need to find another shaft. I’m assuming that all the front of the driveshafts are 16 otherwise I might have to change gearboxes or make hybrid shaft.

I just thought I’d share this little gem with you.

Last edited by touchwoodsden on Mon Jun 20, 2016 5:16 am; edited 1 time in total