1

water - oil pump again, anybody seen this issue Sat Jul 07, 2018 3:10 pm

water - oil pump again, anybody seen this issue Sat Jul 07, 2018 3:10 pm

charlie99

VIP

whilst attempting to dig deep into the bowls of the redframe motor to replace the output shaft

success in removing all te bell housing bolts (except for the alternator drive on the aux shaft )

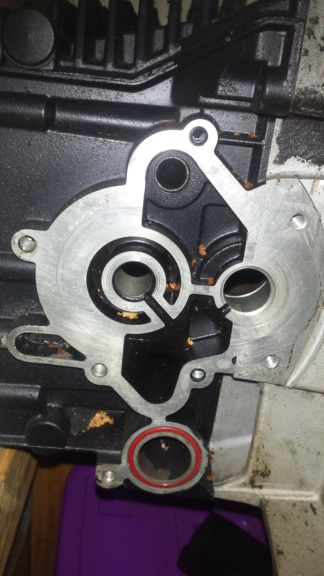

I needed to remove the water pump

all screws removed but it would not come free

I had to remove the impeller , bolt etc and pull the shaft back through the housing , blast , as ive probably screwed the seals now

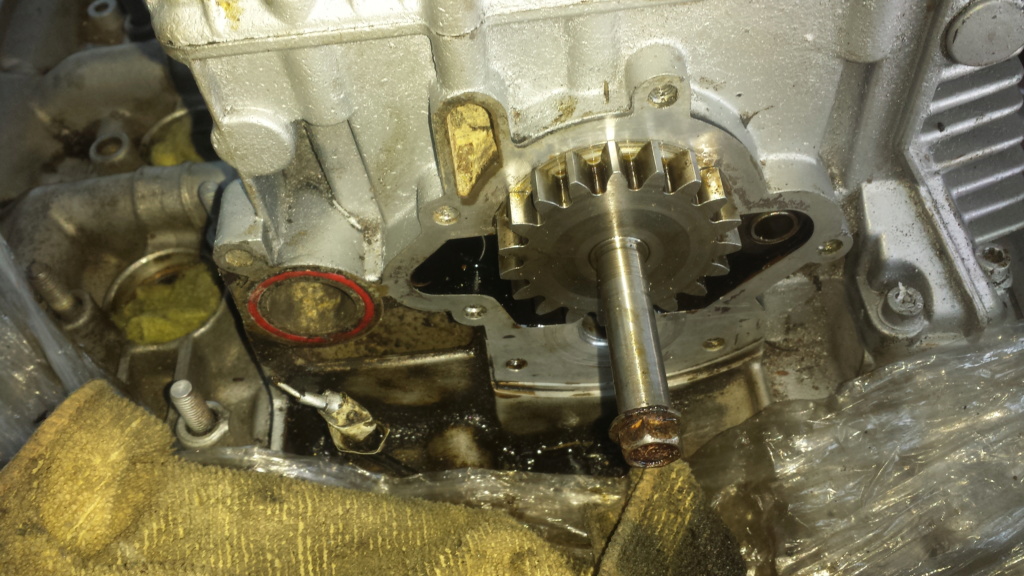

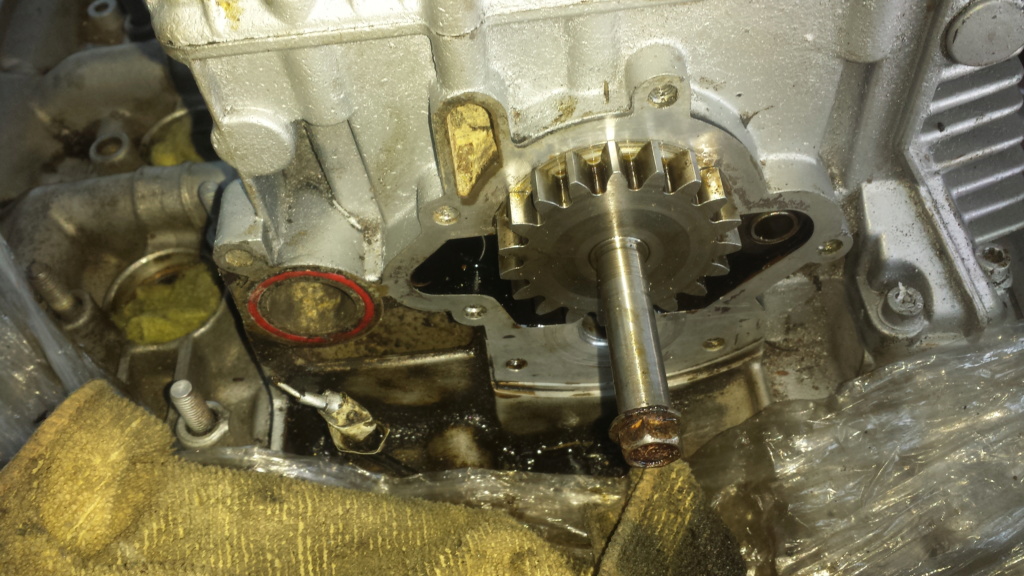

the driven shaft which holds the impeller is stuck fast in the housing

beneath the gear on the face of the sump are score marks , so likely someone has been in there before me

rotation of the shaft is firm but not as I remember, free

if pushing the shaft through the housing from internal to the sump I get about 10 though then it all goes hard to move at all

im thinking a rotten install has spun the metal of the sump to the shaft

so what to do …

whats the Kollective thought to remove it

success in removing all te bell housing bolts (except for the alternator drive on the aux shaft )

I needed to remove the water pump

all screws removed but it would not come free

I had to remove the impeller , bolt etc and pull the shaft back through the housing , blast , as ive probably screwed the seals now

the driven shaft which holds the impeller is stuck fast in the housing

beneath the gear on the face of the sump are score marks , so likely someone has been in there before me

rotation of the shaft is firm but not as I remember, free

if pushing the shaft through the housing from internal to the sump I get about 10 though then it all goes hard to move at all

im thinking a rotten install has spun the metal of the sump to the shaft

so what to do …

whats the Kollective thought to remove it

__________________________________________________

cheezy grin whilst riding, kinda bloke ....oh the joy !!!! ...... ( brick aviator )

'86 K100 RT..#0090401 ..."Gerty" ( Gertrude Von Clickandshift ) --------O%O

'86 k100 rs.. #######.. "Fred " (f(rame) red ) ( Fredrick leichtundschnell ) - -

bits and pieces from many kind friends across the k100 world ...with many thanks ..

1987 k100rs ######## "Red" - (red sports rs TWB style )

1989 K100rt #009637 "Black Betty" (naked rt ala Nigel , now sporting an rs main fairing )