1

OEM Heat Shield Temporary Attach to OEM Exhaust For Provincial Inspection Sat Feb 10, 2024 5:08 am

OEM Heat Shield Temporary Attach to OEM Exhaust For Provincial Inspection Sat Feb 10, 2024 5:08 am

Chris350

active member

Hi,

Tell me that I'm nuts here.

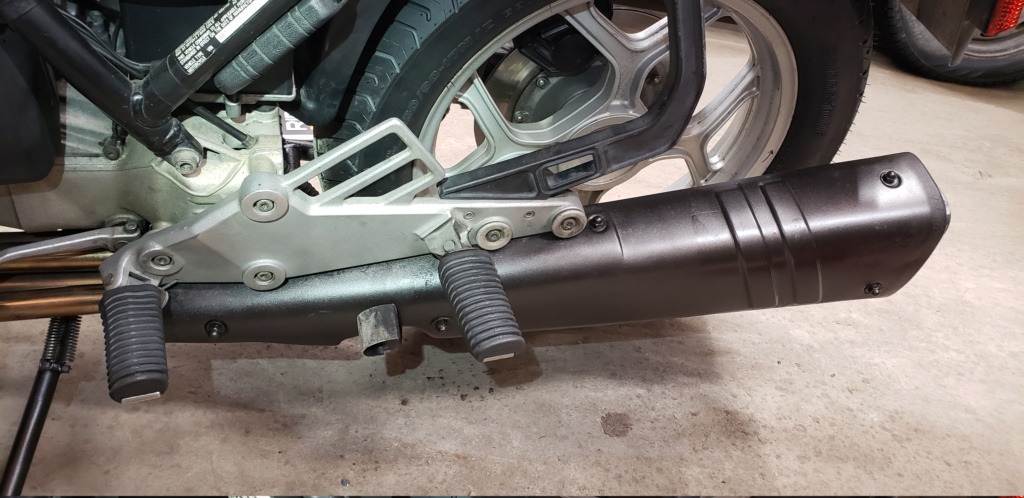

As part of a provincial inspection (Alberta, Canada) to get my bike registered in my province, my stock 85' K100 requires the heat shield to be attached to the exhaust.

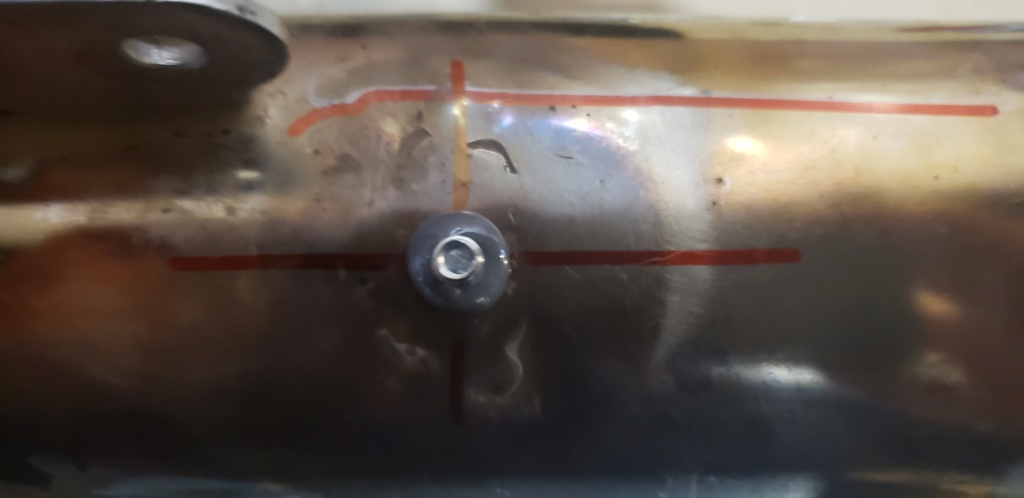

The previous owner removed the heat shield at some point and ran the bike for years and years without. They also ground down the tabs completely flush. After this inspection I want to run the bike without the heat shield forever.

I've acquired a secondhand heat shield and want to temporarily attached it to the stock exhaust for the ride to the inspection (private motorbike shop), for the 20 minute inspection, and the ride home where I'll remove it. We don't have annual inspections or anything like that so it's probably 20 mins of riding and 20 minutes inspection.

I don't think a metal hose/band clamp or similar is going to pass.

Some options.

1. Buy all the OEM parts, clips, square nuts, etc and do it right.

2. I have seen this: https://www.k100-forum.com/t1411-installing-a-bmw-muffler-repair-kit-p-n-95009000390

3. JB high temp weld some bolt heads to the exhaust, add some nuts to add some distance up the bolt, place heat shield and then washer / acorn nut it down

4. Similar to 2 but with socket sex / sleeve bolts

Any other ideas?

Thanks

Tell me that I'm nuts here.

As part of a provincial inspection (Alberta, Canada) to get my bike registered in my province, my stock 85' K100 requires the heat shield to be attached to the exhaust.

The previous owner removed the heat shield at some point and ran the bike for years and years without. They also ground down the tabs completely flush. After this inspection I want to run the bike without the heat shield forever.

I've acquired a secondhand heat shield and want to temporarily attached it to the stock exhaust for the ride to the inspection (private motorbike shop), for the 20 minute inspection, and the ride home where I'll remove it. We don't have annual inspections or anything like that so it's probably 20 mins of riding and 20 minutes inspection.

I don't think a metal hose/band clamp or similar is going to pass.

Some options.

1. Buy all the OEM parts, clips, square nuts, etc and do it right.

- Seems like a bit of work for taking it off afterwards, if done correctly I guess I'd probably keep the heat shield on

- I do have access to a welder but I've never welded in my life, I understand the exhaust is SS and I believe that complicates welding even more

2. I have seen this: https://www.k100-forum.com/t1411-installing-a-bmw-muffler-repair-kit-p-n-95009000390

- I'm not keen on drilling holes into the exhaust

3. JB high temp weld some bolt heads to the exhaust, add some nuts to add some distance up the bolt, place heat shield and then washer / acorn nut it down

- Tell me if this is just dumb

4. Similar to 2 but with socket sex / sleeve bolts

- Tell me if this is just dumb

Any other ideas?

Thanks