1

Engine mount rubber bushings Thu Nov 19, 2020 5:44 pm

Engine mount rubber bushings Thu Nov 19, 2020 5:44 pm

BrickedOut

active member

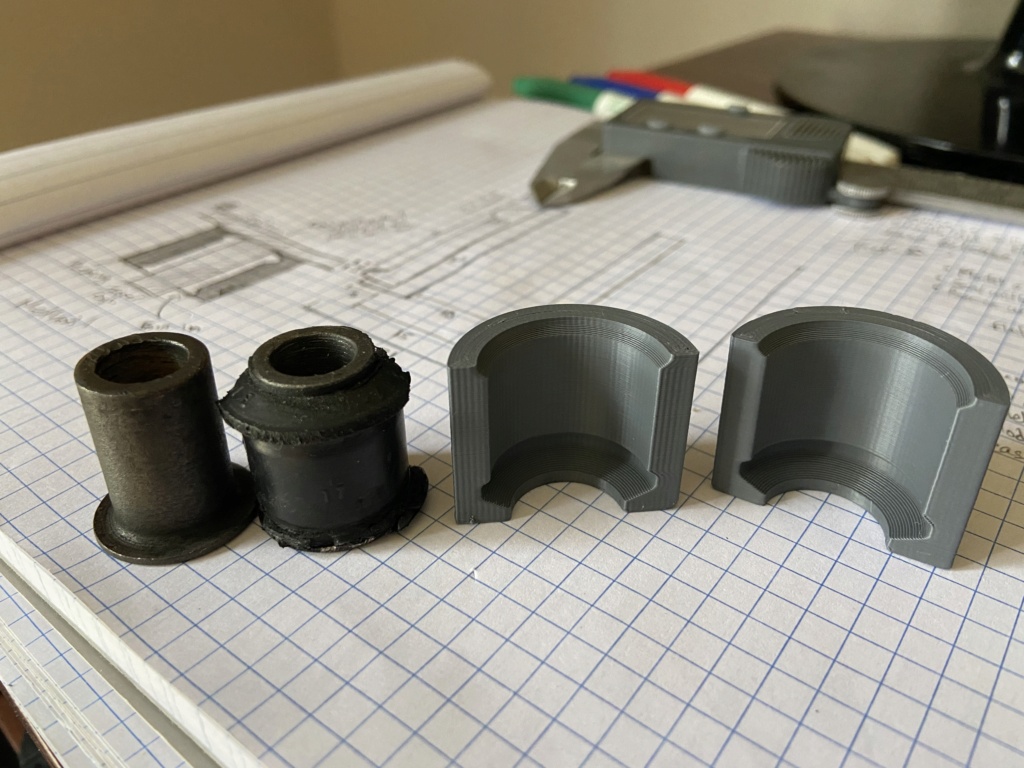

I recently took off my frame for some major modifications and decided to do a powder coating job to seal everything up. That meant I had to take out the front rubber mounts. Besides already being damaged, I made things even worse pulling them out and they’re fairly hard after over 20 years of service.

I looked online to see if they were available and was a bit surprised to find it was over $170 shipped for a pair of them. I’m not a big fan of that price so I thought I’d have a try at making my own using a polyurethane rubber casting.

Wanted to see if there is interest from others who also have damaged mounts or would simply like to replace the old hard rubber for better vibration damping. Planning on trying a few different methods with different rubber mixes to find what works best but I’m guessing I could make them for about $30/pair.

Not sure if there’s other rubber parts that have dwindling stock and equally high prices but I could possibly do the same for them if there’s enough interest.

I looked online to see if they were available and was a bit surprised to find it was over $170 shipped for a pair of them. I’m not a big fan of that price so I thought I’d have a try at making my own using a polyurethane rubber casting.

Wanted to see if there is interest from others who also have damaged mounts or would simply like to replace the old hard rubber for better vibration damping. Planning on trying a few different methods with different rubber mixes to find what works best but I’m guessing I could make them for about $30/pair.

Not sure if there’s other rubber parts that have dwindling stock and equally high prices but I could possibly do the same for them if there’s enough interest.