1

k100 electric screen fitting advice please Sat Jun 09, 2012 5:27 pm

k100 electric screen fitting advice please Sat Jun 09, 2012 5:27 pm

88

Life time member

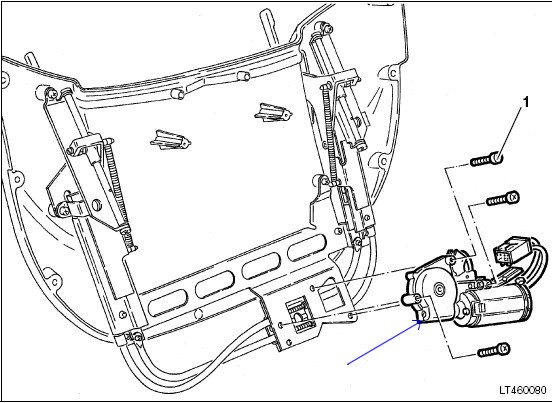

Left side....

right side - neat fit, very little needed to be removed....

sorry for the small pics but I'm having trouble uploading the bigger ones.

88KE

__________________________________________________

88....May contain nuts!

88....May contain nuts!

"The world is a book and those who do not travel read only one page." - St. Augustine from 1600 years ago & still true!

K1 - 1989 - AKA Titan (unique K1/K1100RS hybrid by Andreas Esterhammer)

K1100RS - 1995. AKA Rudolf Von Schmurf (in a million bits)

K100RS - 1991 AKA Ronnie. Cafe racer project bike

K75RTP - 1994

K75C - 1991 AKA Jim Beam. In boxes.

K1100LT 1992 - AKA Big Red (gone)

K100LT - 1988 - AKA the Bullion brick. Should never have sold it.