robmack wrote:I don't profess to be an expert in TB syncing so I am quoting the experts:

K throttle Body Synching By: Rob Lentini

June 1995

Here's a real simple way to ascertain whether your K'sthrottle plates are in synch--the adjustment we are admonished to never touch!

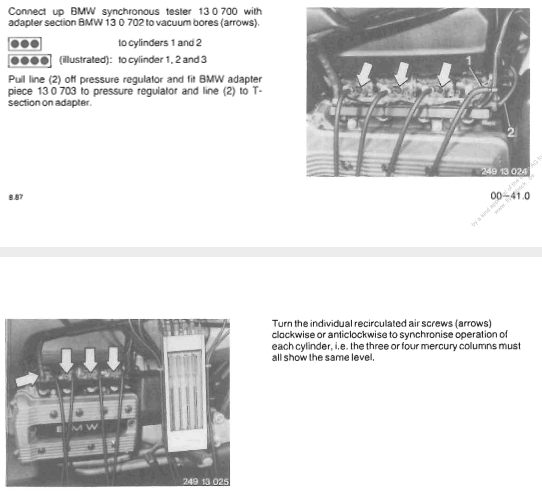

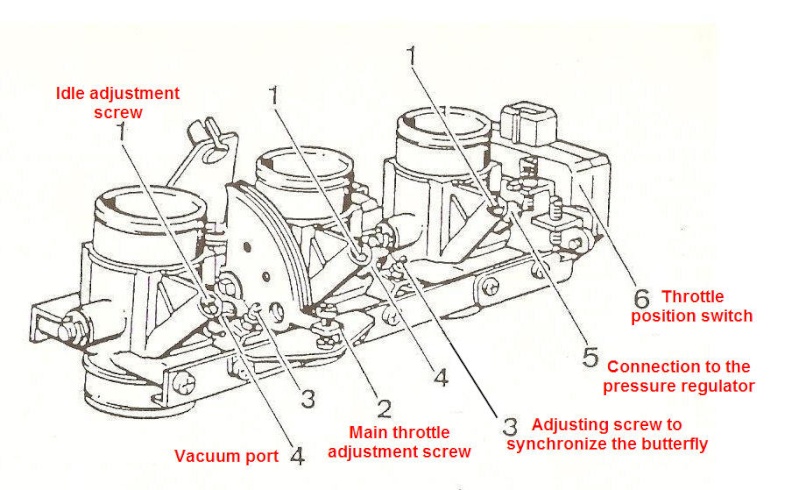

Attach a carb stix, other mercury synchronizer, or veryaccurate bourdon tube vacuum gages to each vacuum access port (covered byrubber caps and the fuel pressure regulator line). Connect the loose fuelpressure regulator vacuum line to the corresponding carb stix column (or gauge)using a "T" fitting.

Warm the engine. Screw in and lightly seat all three (orfour) idle bypass synch adjustment screws (count the turns in for each, andrecord). Doing this will slow or stall the engine, so actuate the startinglever (choke) to maintain normal idle speed**[see amended procedurebelow-wd]**.

When the screws are fully seated, any measured vacuumimbalance is then a function of variance in throttle plate opening ONL Y, andis adjustable from between the throttle bodies. If out of synch, carefullyadjust to equalize all readings. At this point, increase RPM slowly andsmoothly, checking for different readings at various engine speeds.

You should see little or no change, since adjustment atthe smallest throttle opening is most critical. Once throttle plate synch isset, reopen the idle bypass synch adjustment screws (per your notes), andfine-adjust them to re-establish correct idle speed and synchronization withthe "choke" lever off.

Following this procedure should not affect the adjustmentof the throttle switch/position transmitter. Check if in doubt. On older Ksyou're listening for an audible "click" just as the throttle returnsto the closed position. Follow this procedure and your perfect throttle bodysynchronization will eliminate much vibration.

*AMENDED PROCEDURE* I stand corrected! A few days ago I shared with all a procedureto synch the throttle bodies of K motors. In it, I suggested using the chokelever to maintain idle speed while the bypass screws were closed and thebutterflies checked for equal vacuum (and adjusted if required).

Joe Senner and Tom Coradeschi pointed out a problem, one Ihadn't thought about. Their contention was that the choke opens the butterfliesfrom the aft end, while the throttle cable itself actuates from the center.Both guys said vacuum differences would be measured between these two methods,and opening the throttle through the twist grip was the correct way.

Anal as I am, I assured Tom I would verify his empiricaldata right away, so I jumped on the K last night to vindicate myself (everybodyhas an ego!).

Using my Carb Stix, I measured a 2-3 cm delta in themercury column between injector body number 3 (the aft one) and the other twowhen switching from throttle to choke actuation. Whether this is enough tocause vibration or rough running is debatable. Yet, the whole point of doing thesynch procedure is to "knats ass" the adjustment.

And the following comes from Don Eilenberger from another forum. Also good advice for an owner who had fiddled with the linkage screws:

Well - let’s try getting it back to some semblance ofrunning correctly.

- - First - do you have a manual, if so which one? If not BUY one right now. Clymer or Haynes.

- - The bike needs to be checked for intake leaks. At 23 years old - you more than likely have some. Move the bike outside your garage. Have a fire extinguisher handy. Start the bike, let it idle. Take some FLAMMABLE carb cleaner spray and spray very small spritz's around the injectors and the throttle bodies. ANY CHANGE in idle indicates a leak. FIX THE LEAKS before going any further. Try not to start a fire - there is hot exhaust right on the bottom of the head. If you don't know if your skill level is good enough for doing this STOP and find someone who has the necessary skill level. I don't want you burning your house down.

- - The bike has to have the valves precisely adjusted. You're going to be using the engine as an air-pump for a flow bench. Without the valve adjustment it just isn't going to work. They have to be adjusted right, and the closer you can get them to each other the better this is going to work.

- - OK - once the above is done - remove all the brass screws. Clean them and use a Q-tip in carb cleaner to clean the bores they go into. Replace the O rings on them. Screw them in until they *gently* bottom out - then open each of them exactly one turn. IF there are any steps on them from over tightening them - replace them. You can't adjust damaged ones.

- - Remove the throttle-position-switch from the rearmost TB. We'll get to replacing and adjusting it when we're all done here.

- - Connect the 4-channel vacuum gauges. Start the bike. See how it looks at idle. Since you've already misadjusted the inter-TB screws, we'll start there. Adjust these screws until all channels read the same. We're not worrying a lot about idle speed, but don't turn them all in the same direction. Balance the vacuum on them.

- - Open throttle to 2,000 RPM. Do all of the channels change at the same rate? If not - you're going to have to adjust the inter-TB screws at 2,000 RPM until they do. Once you get that right, we're going back to an idle balance adjustment

- - Once all channels look the same at 2,000 RPM, drop back to idle (~1,000 RPM). If the channels aren't balanced - use the brass screws to balance them out. You should not have any brass screw more than 1/2 turn different from the rest. If you do - then the inter-TB screws still aren't correct, and you have to repeat the steps above. (ALL brass screws should be between 1/2 turn and 1.5 turns out. None should be out more than 1.5 turns, and none in more than 1/2 turn.

Once all this is done - the vacuum gauges should move in sync with each otherfrom 1,000 RPM - to about 5,000 RPM. If they don't - repeat the steps above.

Doing this without eliminating any leaks and adjusting the valves is futile,and I'd suggest taking the bike to a dealer if you can't do these first. Youcan only do this - and even then it's going to be difficult - with thecylinders drawing the same vacuum.

Hopefully at this point - you have balanced TB's. You should use the centralidle adjustment screw to set the basic speed. If you didn't unscrew all thebrass screws more than 1.5 turns out - it should fall within the range of thisscrew.

Finally - reinstall the TPS that we removed above. Turn it counter clockwiseuntil you JUST hear it click with the throttles closed. Turn the grip to fullyopen the throttle-bodies and you should hear it click again. What you don'twant to happen is have the throttle-bodies held open by this switch.

How to balance the throttle bodies? (SOLVED) Thu Sep 16, 2010 5:32 pm

How to balance the throttle bodies? (SOLVED) Thu Sep 16, 2010 5:32 pm

1986 k75, 1985 K100rt,

1986 k75, 1985 K100rt,