charlie99

VIP

Number of posts : 11691

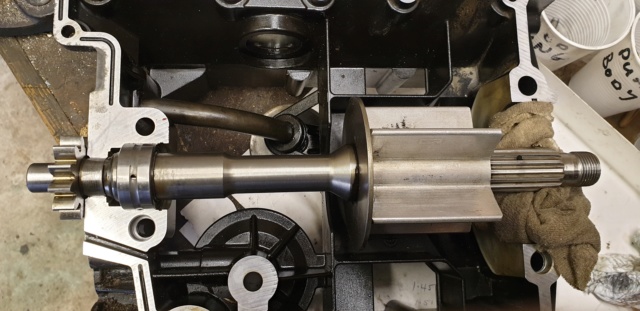

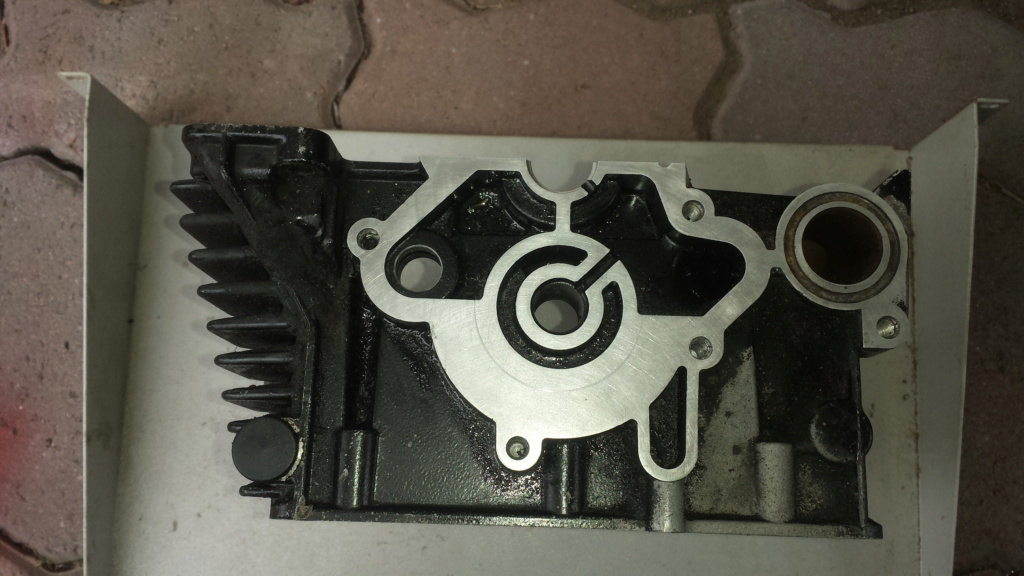

the oil pump has a path to the inner shaft of the small gear ...and the inner part of the large gear

this lets oil at high pressure side lubricate the shafts in the oil pump housing ...obviously at a loss rate depending clearances

further output of this pressure is presented at the outer bearing surface of the output shaft front roller ....so it flows through the bearing , captured in the sump - crank union

dont forget that there is a small o ring in the small gear inner , as a retainer and seal to prevent oil traversing the inner core of the output shaft , directing the oil to- through the roller bearing , after which falls to the sump

hope that helps ?

__________________________________________________

cheezy grin whilst riding, kinda bloke ....oh the joy !!!! ...... ( brick aviator )

'86 K100 RT..#0090401 ..."Gerty" ( Gertrude Von Clickandshift ) --------O%O

'86 k100 rs.. #######.. "Fred " (f(rame) red ) ( Fredrick leichtundschnell ) - -

bits and pieces from many kind friends across the k100 world ...with many thanks ..

1987 k100rs ######## "Red" - (red sports rs TWB style )

1989 K100rt #009637 "Black Betty" (naked rt ala Nigel , now sporting an rs main fairing )

needle bearing oil feed Wed Feb 19, 2020 12:14 pm

needle bearing oil feed Wed Feb 19, 2020 12:14 pm